Failure analysis is definitely the systematic investigation of a component failure with the targets of analyzing the foundation triggers of failure and also the corrective actions desired to circumvent future failures.

Identify potential results in of failure in column E. Explain these regarding something which is often corrected or could be controlled.

A broader failure investigation might need a root lead to analysis (RCA) to establish weaknesses or gaps inside of a administration system. A root bring about analysis can help determine corrective steps, reduce recurrence and help save charges in the future.

Determining the root failure results in In several cases, equipment failures are surface area-level manifestations of further challenges that were not tackled in time. At times, a combination of different factors results in an unexpected breakdown. Due to the fact breakdowns are so high-priced and disruptive, maintenance teams need to put many energy into blocking them. Besides program maintenance, pinpointing root failure leads to – and getting rid of them – is The simplest way to continue to keep breakdowns at bay.

) The principle of FMEA is rather basic and commonly recognized, but in practice, a tremendous variation in high quality and competency exists. Confusion and various views about how to manage particulars exist. This article sheds some light on popular confusion and disputes.

The 2nd theory is that when a component failure is uncovered, at any position within the click here FFA course of action, it really is declared defective irrespective of whether the failure can or cannot be reproduced.

It consists of identifying, being familiar with, and addressing the root brings about of a failed final result, along with the classes and steps that may be derived from it. However, conducting a failure analysis isn't always simple or uncomplicated, mainly because it calls for honesty, openness, and significant considering. Here are several best techniques for conducting a failure analysis in a very strategic context.

three. Be mindful from the will cause and consequences of failures. You might be immersing in an endeavor where by there is a appropriate response chain that interlinks many elements that contribute for the failure with the business enterprise.

It provides whoever produced the item with info which can help decide how to handle the issue. The analysis also aids figure out what to do to circumvent upcoming failures.

This research exhibits a number of the many ways failure analysis can be carried out. It generally begins with a nondestructive method of observation, like a criminal offense scene. Then pieces of the fabric are taken from the original piece which are applied in different observations.

Failure analysis can be a method that you should acquire per problem. You will need to be reminded there are diverse triggers of failures and there are also alternative ways on how one can establish them.

How will you establish and enhance your capabilities and expertise in failure analysis for a structural engineer? three contributions

three. Developing an in depth failure analysis procedure can Arrange the methods which have been needed to be taken from the collection of failure impact evidences as many as The easy evaluation of each and every failure’s root causes.

Failure analysis is not really a precise science. It is just a curious exploration in the correct bring about driving failures and it might be viewed as a craft.

Ariana Richards Then & Now!

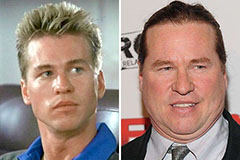

Ariana Richards Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!